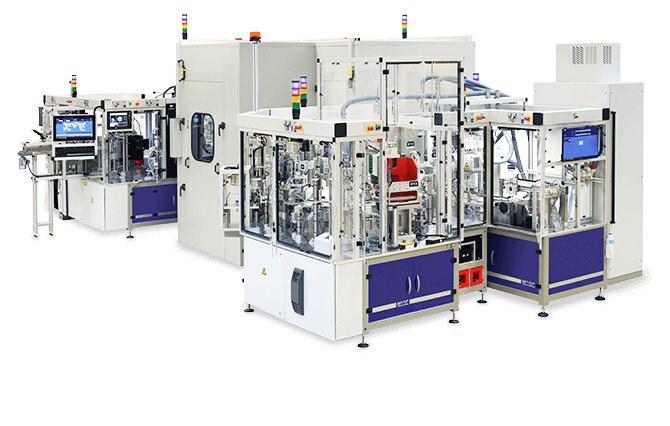

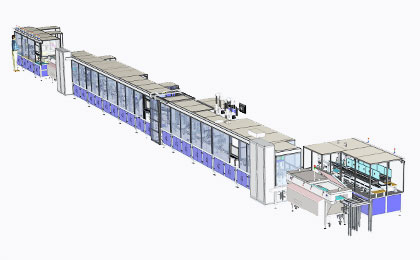

Our high-tech assembly lines are built with innovative processes using units to measure electric values, paths, speeds, forces, moments, pressures, flows, sealing, and also Carthesian, SCARA and multi-axis robots and video controls to supervise assembly operations or measurements.

We also provide the technologies of metering, joining, labelling and packing and machining, such as stamping, bending or orbital riveting. All of this is upgraded with additional competencies in automation, such as the M-FMEA methods and MSA and special knowledge about measuring systems with the PXI and LabView applications.