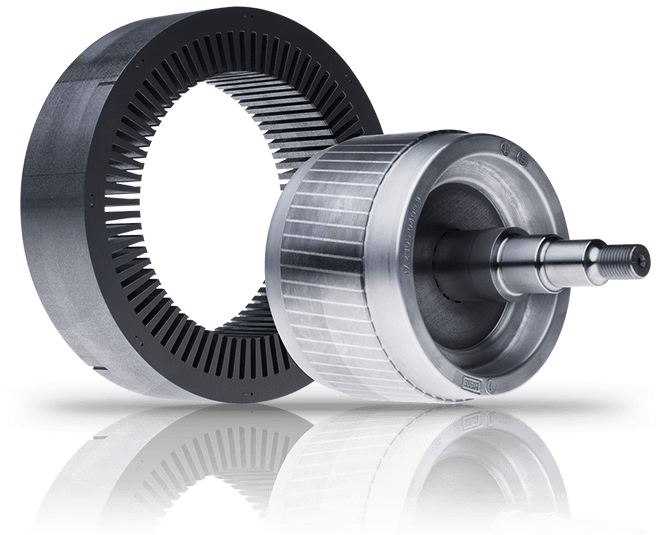

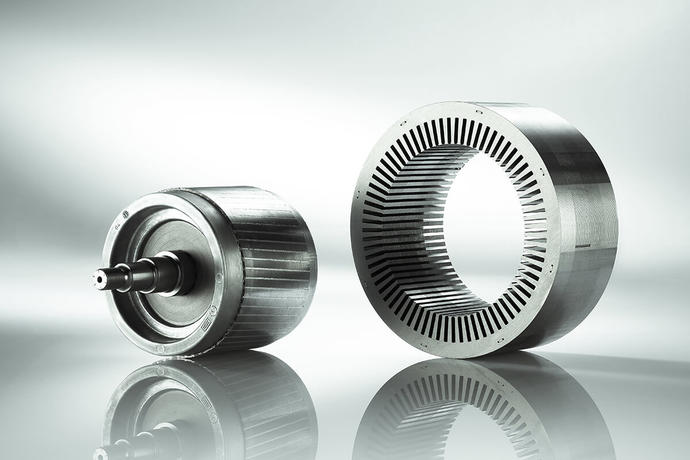

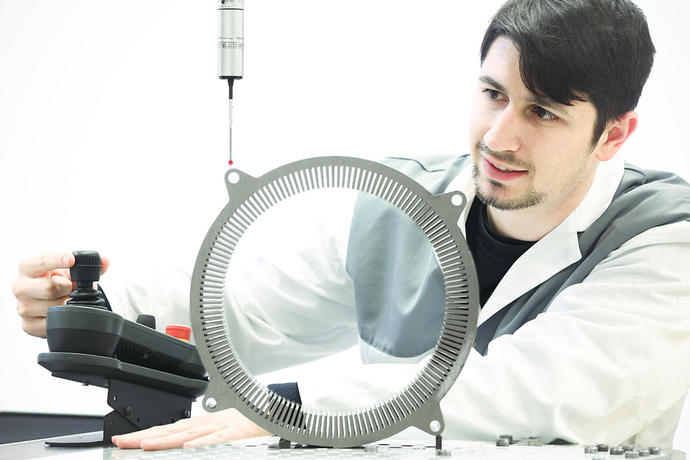

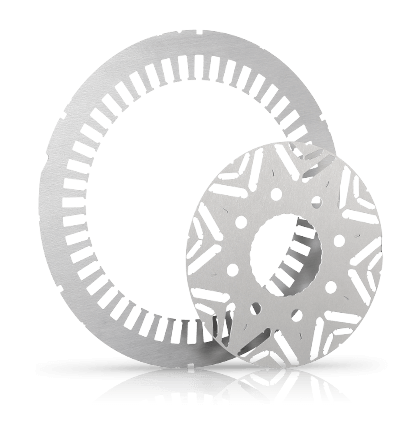

Die-cast rotors are an integral part of high-performance asynchronous electric motors, without which there would be no modern life. We produce them with high pressure die casting where the rotor stacks are filled with aluminium alloys. In the die-casting process, most attention is paid to the control and quality of the input materials, the repeatability of the process parameters and the temperature control of the moulds. This ensures high-quality die casting and minimal porosity.

We use the technology of high-pressure die casting with aluminium alloys to produce die-cast rotors. Technically pure aluminium with good electrical conductivity is generally used in this process.

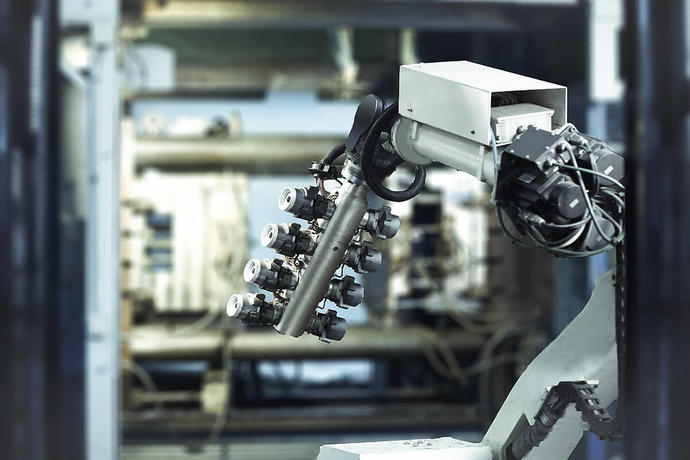

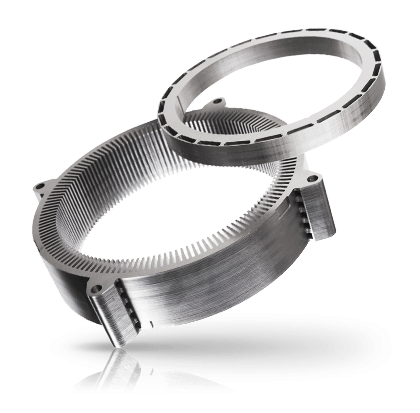

We use the vertical and horizontal rotor die casting technology, with this allowing us to easily adapt to clients’ various requirements and achieve high productivity. We perform other technological processes too, for example, the embedding of shafts on a rotor and the robotic CNC-machining of rotors and rotors with shafts.

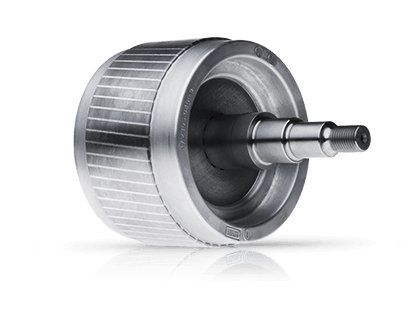

Areas of product application

Die-cast rotors are used in various segments of the automotive industry.