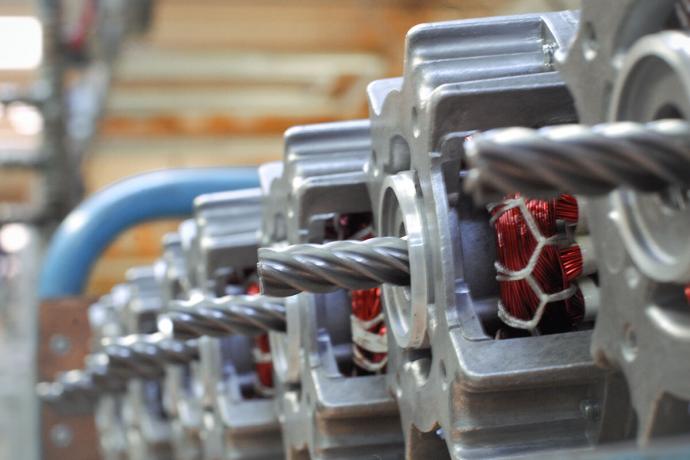

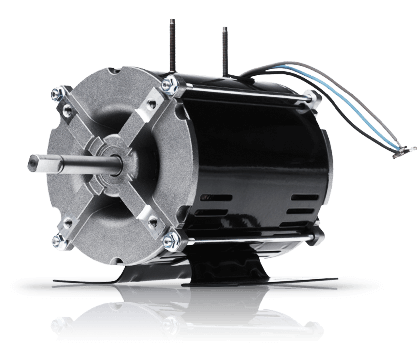

The high-quality production of components and final products – capacitor and hermetical motors requires the internal control of technological processes of lamination packaging into stator and rotor stacks, winding and impregnation of windings, machining of individual components and testing the suitability of the dimensions of all the elements listed. The automated component assembly into the final product – an electric motor before packaging – also includes the 100% final testing of the properties of electric motors and electric and mechanical properties.

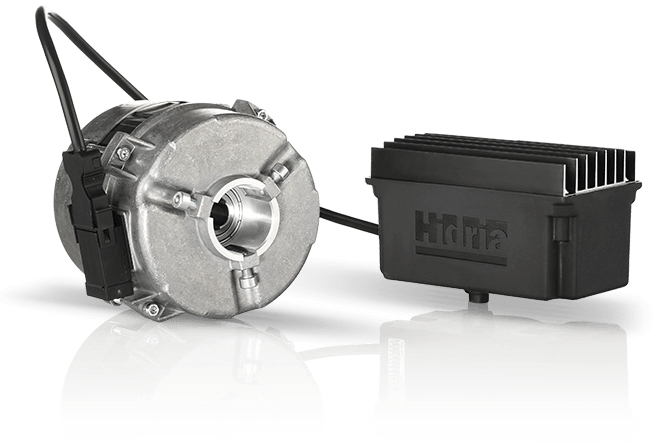

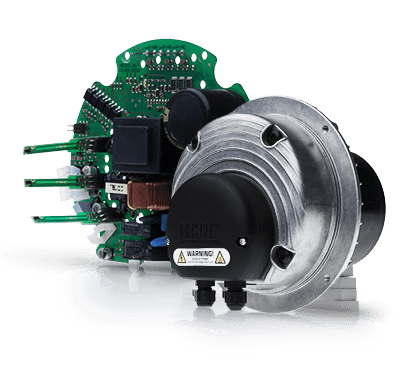

For electric motor drives produced using the EC technology, the listed procedures are supplemented by more complex technological procedures of assembly and magnetising of permanent magnets, the installation of electronic drives – inverters and their programming to achieve compliance with the selected application’s requirements.